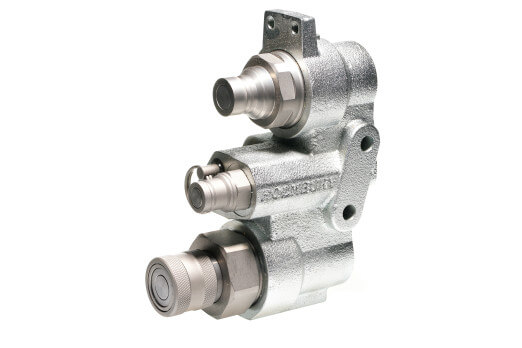

Decompression block couplings

Decompression block

Features

- Decompression achieved by simple pull feature which also prevents accidental system discharge

- All couplings are flat face and are designed to the ISO 16028 Standard

- Low profile coupling design minimises side loading

- Coupling arrangement can be ordered in 1/2” (Size 12) for standard flow or 3/4” (Size 19) for high flow applications

- Case drain coupling is 3/8” (Size 10)

Accessories

- Not applicable

Construction

- HDB block couplings are carbon steel with zinc nickel plating (1200 hours with no red rust in salt spray tests)

- Block body is ductile cast iron

- Fitted with Nitrile and PTFE seals

Applications

- Quick changeover of construction equipment attachments

- Skid steer loaders

- Track loaders

- Excavators

- Compact loaders

- Utility vehicles

AVAILABLE SEALS AND TEMPERATURE RANGE

All carbon steel products have Nitrile Butadiene Rubber seals fitted as standard. All stainless steel products have Fluoro-elastomer Rubber (Viton®) seals fitted as standard. Special seal materials available on request.

0°

Nitrile

EPDM

Viton®

Kalrez®

0°

Viton®

Kalrez®

Nitrile

EPDM

| Abbreviation | Trade Name | Chemical Name | Min Temp. | Max Temp. |

| NBR XNBR | Chemigum®, Hycar8, Breon®, Butakon®, Butacril®, Buna-N®, Perbunan®, Paracril®, Krynac®, Europrene-N®, Nipol® | Nitrile Butadiene Rubber Carboxylated Nitrile Rubber | -40°C (-40°F) | 106°C (223°F) |

| FKM (FPM) | Dai-el®, Fluorel®, Tecnoflon®, Viton® | Fluoro-elastomer Rubber | -20°C (-4°F) | 200°C (392°F) |

| EPR EPDM | Buna-AP®, Dufral®, Epsyn®, Nordel®, Epcar8, Keltan®, Royalene®, Polysar-EPDM® | Ethylene Propylene Copolymer Ethylene Propylene Terpolymer | -50°C (-58°F) | 120°C (248°F) |

| FVMQ | Silastic 1S®, FSE® | Fluorosilicone Rubber | -65°C (-85°F) | 170°C (338°F) |

| FFKM | Perlast®, Kalrez®, Chemraz®, Kaflon® | Perfluoroelastomer | -25°C (-13°F) | 300°C (572°F) |